12V ceramic Heater Element for Milwaukee Soldering Iron

- Description

- Inquiry

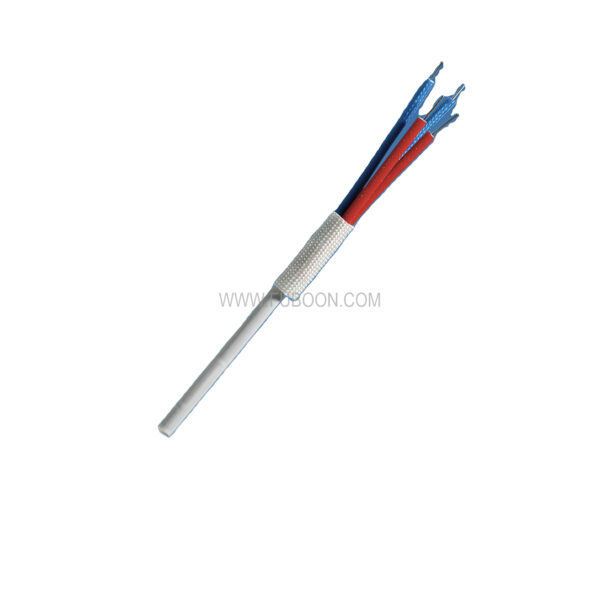

12V ceramic Heater Element for Milwaukee Soldering Iron

Fuboon made lots of 12V MCH ceramic heater which is used for cordless Soldering Iron. It enjoys great advantages of delivers fast application speeds by reaching operational temperature in under 18 seconds and maintaining an optimized temperature throughout the most demanding applications.

12V ceramic Heater Element

3.Excellent insulation and dielectric strength.

4.Sensor resistance is liner changing along with the temperature rising of heater.

5.Good sensitivity.

6.Safe product which contains no harmful material,i.e.be in line with intermatioal environmental protection standards.

We are producing High Quality Hakko A1321 24V 60W Heating Element for 936 Soldering Station with the advantages of

energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Part No. | Specification(mm) | Voltage | Heating Resistance |

AH60790301 | L60*φ3.8mm | 24VAC | 3.0±0.3 |

AH60790364 | L60*φ3.8mm | 220VAC | 140±10% |

AH60790331 | L60*φ4.3mm | 24VAC | 1.75±0.25 |

AH60790308 | L60*φ3.8mm | 110VAC | 310Ω±10% |

AH60790312 | L70*φ4.0mm | 110VAC | 125Ω±10% |

AH60790313 | L70*φ4.0mm | 110VAC | 175Ω±10% |

AH60790309 | L80*φ5.0mm | 100VAC | 37Ω±15% |

12V ceramic Heater Element

Basic dimension:

1.12V

2.Dimension:Standard size or customised

3.Resistance:Accordingly

4.Lead:four nickel leads

5.Sleeve: red,blue and white or accordingly

6.FOR Cordless Soldering Iron

Advantage:

1)Long lifetime:airproof constructure for conquering the disintegration problem

(2)Quick temperature rise and stable temperatures can be achieved–usefulness for every

required heat setting

(3)Excellent insulativity

(4)Energy efficient and high efficiency thermal conductivity—be able to generate heat internally

and externally simultaneously.

(5)Small volum and compact structure

(6)Equalized heat distribution and high power density.

(7)Safe and eco-friendly electronic product complying to the RoHS

requirements:MCH contains no harmful materials.

(8)High cost performance

(9)Our organization in conformity with ISO9001:2008.